The Art and Science of Cutting and Bending Sheet Metal

Whether you’re crafting aircraft components, automotive panels, or custom enclosures, cut and bend sheet metal techniques are fundamental to modern manufacturing.

These processes combine precision, geometry, and physics — demanding both skill and the right equipment. From laser cutting to CNC press brake bending, mastering these methods can dramatically improve production efficiency and reduce material waste.

According to a report by MarketsandMarkets, the global sheet metal fabrication services market is expected to reach $21.7 billion by 2028, driven by automation and smart manufacturing technologies.

Understanding Sheet Metal Fabrication Basics

Before diving into advanced methods, it’s crucial to understand what sheet metal fabrication entails.

What Is Sheet Metal Fabrication?

It’s the process of cutting, bending, and assembling thin metal sheets (usually less than 6mm thick) into functional components. Common materials include:

-

Aluminum – lightweight and corrosion-resistant.

-

Steel – strong and versatile for construction and automotive use.

-

Stainless steel – ideal for hygienic or outdoor applications.

-

Copper and brass – used for decorative or electrical parts.

Key Techniques: Cutting and Bending

1. Cutting Techniques for Precision

Cutting is the first step in the fabrication process — defining shape and dimension. The choice of method depends on material type, thickness, and desired accuracy.

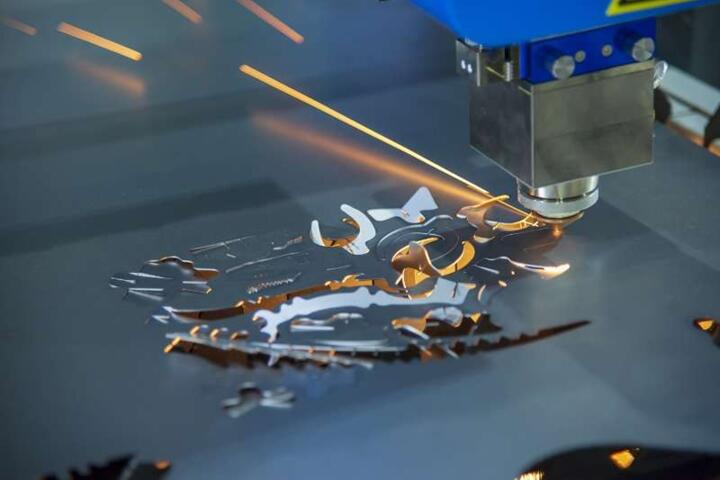

A. Laser Cutting

Laser cutting uses focused light to melt or vaporize material.

Advantages:

-

Extremely precise (±0.1 mm tolerance).

-

Minimal burrs and smooth edges.

-

Compatible with automation.

Best for: Intricate designs in aluminum or stainless steel.

Example: Trumpf and Bystronic laser systems dominate the industrial market for high-speed precision cutting.

B. Waterjet Cutting

A high-pressure jet of water mixed with abrasive particles cuts through metal without heat.

Advantages:

-

No heat-affected zones (ideal for heat-sensitive materials).

-

Can cut up to 200 mm thick.

Drawback: Slower than laser cutting for thin sheets.

Example: Flow International specializes in industrial-grade waterjet systems for aerospace and defense.

C. Plasma Cutting

Plasma cutters use electrically conductive gas to cut metals.

Advantages:

-

Efficient for thick steel (up to 50 mm).

-

Cost-effective for heavy-duty work.

Downside: Produces rougher edges compared to lasers.

D. Mechanical Shearing

Uses a blade to cut straight lines in sheet metal.

Advantages:

-

Fast and inexpensive for simple cuts.

-

No heat distortion.

Best for: Large-scale cutting of mild steel or aluminum sheets.

2. Bending Techniques for Accuracy and Repeatability

Once the metal is cut, it’s shaped through bending — a process that transforms flat sheets into functional geometries.

A. Press Brake Bending

A press brake applies force via a punch and die to form angles.

Key Factors:

-

Material thickness: Affects spring-back (tendency to return to original shape).

-

Bend radius: Should be at least equal to material thickness to avoid cracking.

-

Tonnage: Required force calculated per material and bend length.

Example: Amada and Bystronic press brakes are renowned for precision bending in the aerospace and electronics industries.

B. Roll Bending

Uses a set of rollers to create curves or cylindrical forms.

Best for: Pipes, tanks, and architectural components.

C. Folding Machines

Folding systems hold the sheet while a beam lifts it to create folds.

Advantages:

-

No tool marks on material.

-

Excellent for large sheets or complex shapes.

Example: Radan CAD/CAM software integrates folding simulations for accurate predictions.

D. CNC Bending

Computer Numerical Control (CNC) ensures consistency and repeatability.

Benefits:

-

High accuracy and automation.

-

Reduces human error.

-

Stores bend programs for future runs.

CNC press brakes from Salvagnini and Trumpf are industry favorites for precision parts manufacturing.

Key Factors for Precision and Efficiency

1. Material Properties

Each metal behaves differently under stress.

-

Aluminum bends easily but can crack under sharp angles.

-

Stainless steel requires more force and precise control.

-

Mild steel offers good flexibility but risks rusting if untreated.

Tip: Use bend allowances and compensation tables to account for elongation during forming.

2. Tooling Selection

Choosing the right die and punch shape directly impacts quality.

Common Tools:

-

V-dies for 90° bends.

-

Radius dies for gradual bends.

-

Gooseneck punches for return flanges.

Pro Tip: Use precision-ground tooling to reduce wear and maintain consistent results.

3. CAD/CAM Integration

Modern fabrication integrates design and production through CAD/CAM software like SolidWorks, AutoDesk Fusion 360, or BySoft 7.

Benefits:

-

3D simulation prevents costly errors.

-

Automatically calculates flat patterns.

-

Exports directly to CNC machines.

Fact: A study by SME.org found that CAD-driven manufacturing improves material efficiency by up to 18%.

4. Quality Control and Measurement

Precision requires regular inspection using tools such as:

-

Digital calipers and micrometers for thickness checks.

-

Laser measurement systems for dimensional accuracy.

-

Coordinate Measuring Machines (CMMs) for 3D validation.

Common Mistakes to Avoid in Sheet Metal Cutting and Bending

-

Ignoring Material Grain Direction: Can cause cracking or warping.

-

Incorrect Bend Radius: Leads to structural weakness.

-

Neglecting Spring-Back Compensation: Causes inaccurate angles.

-

Overlooking Heat Distortion in Laser/Plasma Cutting: Impacts assembly alignment.

-

Skipping Deburring: Sharp edges may compromise safety and coatings.

Tip: Always perform trial bends on scrap material to confirm angles before mass production.

Safety Considerations

Safety is non-negotiable in metal fabrication.

Best Practices:

-

Wear cut-resistant gloves and face shields.

-

Use proper ventilation during plasma or laser cutting.

-

Keep clear of pinch points in press brakes.

-

Follow OSHA and ISO 23125 machine safety standards.

Automation tools, like ABB and KUKA robotic arms, also enhance safety by reducing manual handling.

The Role of Automation in Sheet Metal Fabrication

Modern fabrication is shifting toward Industry 4.0, where machines communicate and optimize production autonomously.

Smart Features Include:

-

AI-assisted bend corrections in CNC press brakes.

-

Automatic tool changers to minimize downtime.

-

IoT monitoring for predictive maintenance.

Example: Salvagnini L5 systems use adaptive technology to adjust laser power in real time, maintaining consistent quality across varying materials.

Fact: According to Deloitte, automation can increase manufacturing productivity by up to 35% while reducing scrap waste.

Practical Tips for Beginners

-

Start with thin-gauge materials to learn bend behaviors safely.

-

Use a bend allowance calculator for accurate layouts.

-

Keep tooling clean — dust or rust affects precision.

-

Store metal sheets horizontally to prevent warping.

-

Invest in training programs like those offered by Fabricators & Manufacturers Association (FMA) or Coursera’s Manufacturing Process courses.

Author’s Insight

During my years working with precision fabrication for electronics enclosures, I learned one hard truth — the metal always “remembers” its stress. Even small errors in bend radius or grain orientation can cause failures later in assembly.

Our team once switched from manual press brakes to a CNC hydraulic system from Amada, and production efficiency rose by 28% in the first quarter. More importantly, consistency improved across thousands of units.

My advice: Respect the material, calibrate your tools, and let data guide your process. Precision isn’t luck — it’s a discipline.

Conclusion

Mastering cut and bend sheet metal techniques is both an art and a science — requiring precision, experience, and the right technology.

From laser cutting to CNC bending, every step contributes to product accuracy, efficiency, and structural integrity. By understanding materials, using proper tooling, and integrating automation, fabricators can minimize waste and deliver exceptional results.

In today’s competitive market, precision fabrication is not just a skill — it’s a strategic advantage.